Company profile

Excellence on the cutting edge of potassium inorganic derivatives

Altair Chimica has been the first European KOH producer to fully convert to mercury-free membrane cell technology (2005-2008).

The new mercury-free chlor-potash plant of Saline di Volterra, build on green field to avoid any potential mercury contamination, was the first one in Europe and, from a technological point of view, among the most advanced in the world for the production of very pure potassium derivatives.

The new plant allowed over time to cut electricity consumption by 30% and water consumption from the river by 40%: since then, more than 50 Mio € were invested over the last 10 years to increase production capacity and efficiency, to obtain continuous quality improvements, such as chlorates contamination control, and develop new products to extend the product range.

Altair Chimica works everyday to foster a useful and sustainable innovation of processes, technologies and products, in close collaboration with universities (Firenze, Pisa) and the CNR (National Research Council, the largest public research institution in Italy), resulting in several ongoing patenting processes.

Altair Chimica is part of ESSECO GROUP, an Italian family-owned industrial group that offers products and services for the inorganic chemistry and oenology industry. With almost 100 years of history, ESSECO GROUP is directly present in 15 countries of the world with over 1,000 employees.

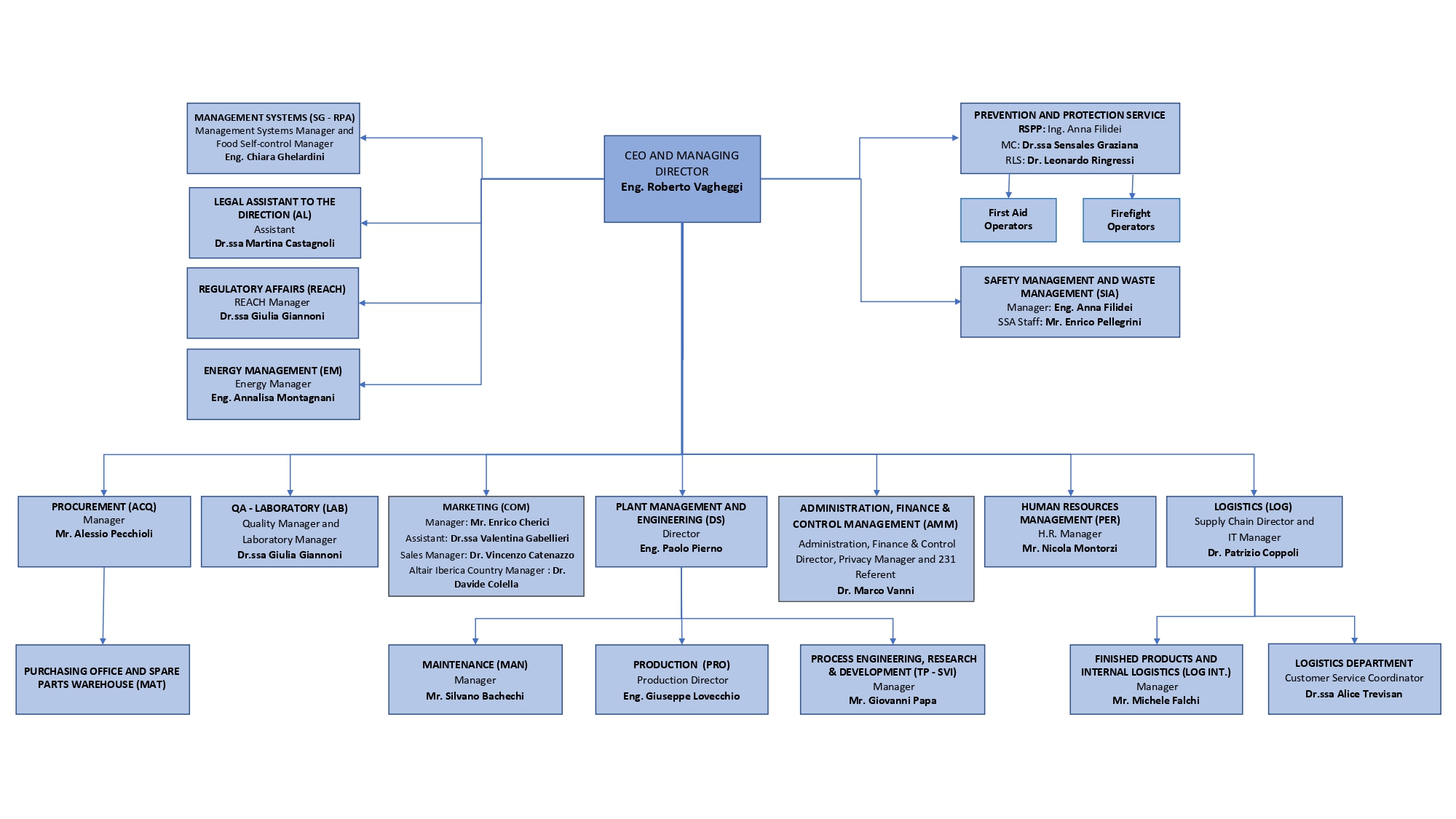

Organization

Altair Chimica believes that people are a great value and an opportunity for the company. For this reason, it constantly invests in resources that guarantee a continuous improvement in the effectiveness of the organization, in customer satisfaction, in the Management Systems operations and in the compliance with regulatory requirements.

The company offers its employees a Staff Training Plan, envisaged by the Company Management System, which includes specific training modules, including the one relating to environmental issues. Staff involvement is the positive element that guarantees the maintenance and successful outcome of all environmental improvement measures.

HISTORY

1959

Larderello S.p.A., a private company with plants in Larderello (Pisa), builds a Chlorine-Soda plant in Saline di Volterra: on July 6th the President of the Italian Republic Gronchi lays the foundation stone of the new chemical plant.

1966

The chemical plants of Saline di Volterra and Larderello, united in the Società Chimica Larderello (SCL), are acquired by ANIC-ENI-SOLVAY.

1974

The Saline plant, which continues to operate as SCL, is entirely owned by ANIC-ENICHEM and subsequently by SAMATEC, also an ENI Group company. By keeping the activities related to the electrolysis process, the company focuses on the chemistry of Potassium and the transformation of Chlorine into products for sanitizing and treating water.

1993

Società Chimica Larderello is privatized and sold to the D.G. HARRIS, American company based in New York.

1995

The industrial complex of Saline di Volterra becomes Altair Chimica S.p.A., a wholly Italian capital company.

2005

Altair Chimica signs an agreement with the Italian Ministry of the Environment and with the EU for the redevelopment and modernization of the Saline di Volterra plant, which provides for the total elimination of mercury from all production processes and the reduction of electricity consumption and water taking from the river nearby.

2008

Altair Chimica completely abandons the mercury cell technology, inaugurating a new plant for the production of totally mercury-free caustic potash, which uses membrane cell technology. The new plant was built from scratch on a “virgin” site (so-called “green field project”) to avoid any potential risk of mercury contamination present in old infrastructures. It was the first European plant of this type and, from a technological point of view, it still is among the most advanced in the world for the production of inorganic potassium derivatives, guaranteeing very high purity products.

The new settlement allows reduce electricity consumption by 30% and a 40% reduction of water withdrawal from the river close by.

2010

Altair Chimica starts an ambitious debottlenecking project, consisting in the optimization of the production plant to increase its overall capacity. This step also included investing in a new plant for the production of hydrochloric acid (HCl).

2011

Altair Chimica becomes part of Esseco Group, family owned Italian industrial group with almost 100 years of history and Altair Chimica main Italian customer for caustic potash (KOH).

2012

Altair Chimica confirms its commitment to reduce electricity consumption with the start-up of a new 4.5 MW cogeneration plant, which also allows the recovery of both, carbon dioxide (CO2) for the production of potassium hydroxide (K2CO3) and hydrogen (H2) for self-production of green energy.

2013

Altair Chimica enters the organic chemistry, starting the production of chlorine-paraffin, with the commercial name “ESSECHLOR”. Significantly increases the production capacity of the Saline plant.

2015

The production capacity of the Saline plant is further increased, bringing the plant target to 55,000 tons / year of chlorine and 87,000 tons / year of 100% caustic potash.

2017

Further investments allows the startup of a caustic potash (KOH) flakes plant with 10,000 tons / year capacity, a pilot plant for the production of food grade solid potassium chloride (KCl) with 3,000 tons / year capacity and a caustic soda (NaOH) solution plant.

2019

Esseco Group acquires the Pieve Vergonte (VB) plant from Hydrochem, whose energy needs are met by the two connected hydroelectric plants of Megolo and Ceppo Morelli. This acquisition contributes to the development of the group’s production capacity in the chloralcali sector which has Altair Chimcia as its leading company.